We design and manufacture…

Screw Conveyors (Shafted & Centreless)

Bespoke screw conveyors, both shafted and shaftless, tailor-made to suit the individual application.

Learn more

Belt Conveyors & Chain Conveyors

Bespoke belt conveyors, horizontal, inclined, shuttle & radial types, tailor-made to suit the individual application. For multiple sectors including the food industry.

Learn more

Reception & Storage Silos

Tailor-made storage silos, storage hoppers and other systems to store a variety of materials.

Learn more

Belt Reception Unit

Custom continuous or batch mixers for a range of materials which can be jacketed for active heating / cooling.

Learn more

Push Floors, Live Bottom Bunkers & Pumps

Live bin systems and reception bunkers for a variety of materials and to suit the specific requirements.

Learn more

Mixers, Blanchers & Rod Washers

Custom continuous or batch mixers for a range of materials which can be jacketed for active heating / cooling.

Learn moreCTM Systems

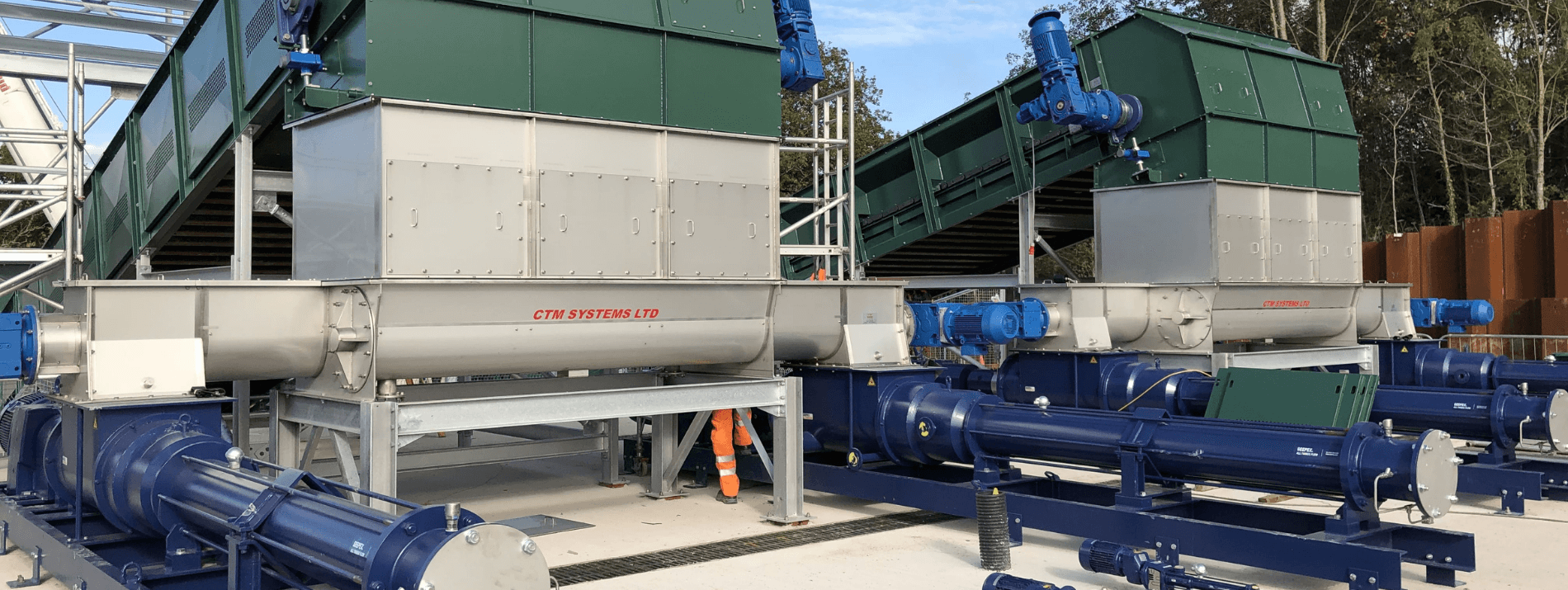

CTM Systems provide one of the UK’s leading bespoke material handling services for large and bulk materials.

With over 40 years’ experience, our highly experienced designers can provide cost effective design solutions utilising our in-house design & manufacturing capability. Also providing full turn key installations, commissioning and product training if required. With a proven track record of producing efficient bespoke handling and storage solutions for a vast range of industry sectors including water treatment, food processing, bio-fuels, waste recycling, chemicals, quarrying to name just a few. Solutions offered are competitively priced. A tailored concept will be produced from the clients initial scope, design criteria and close working relationship with our client, advice can be offered to achieve the optimum control philosophy to ensure the end user is supplied the best solution to operate on a day to day basis.

From design to installation and commissioning we guarantee you an impeccable service, enabling us to keep you and your business running smoothly.

We work within…

Why choose us?

- Bespoke Materials Handling Solutions

- Reliable Equipment

- Turnkey Packages

- Highly Experienced Team

80

years of combined experience

500

completed projects

123

bespoke product designs