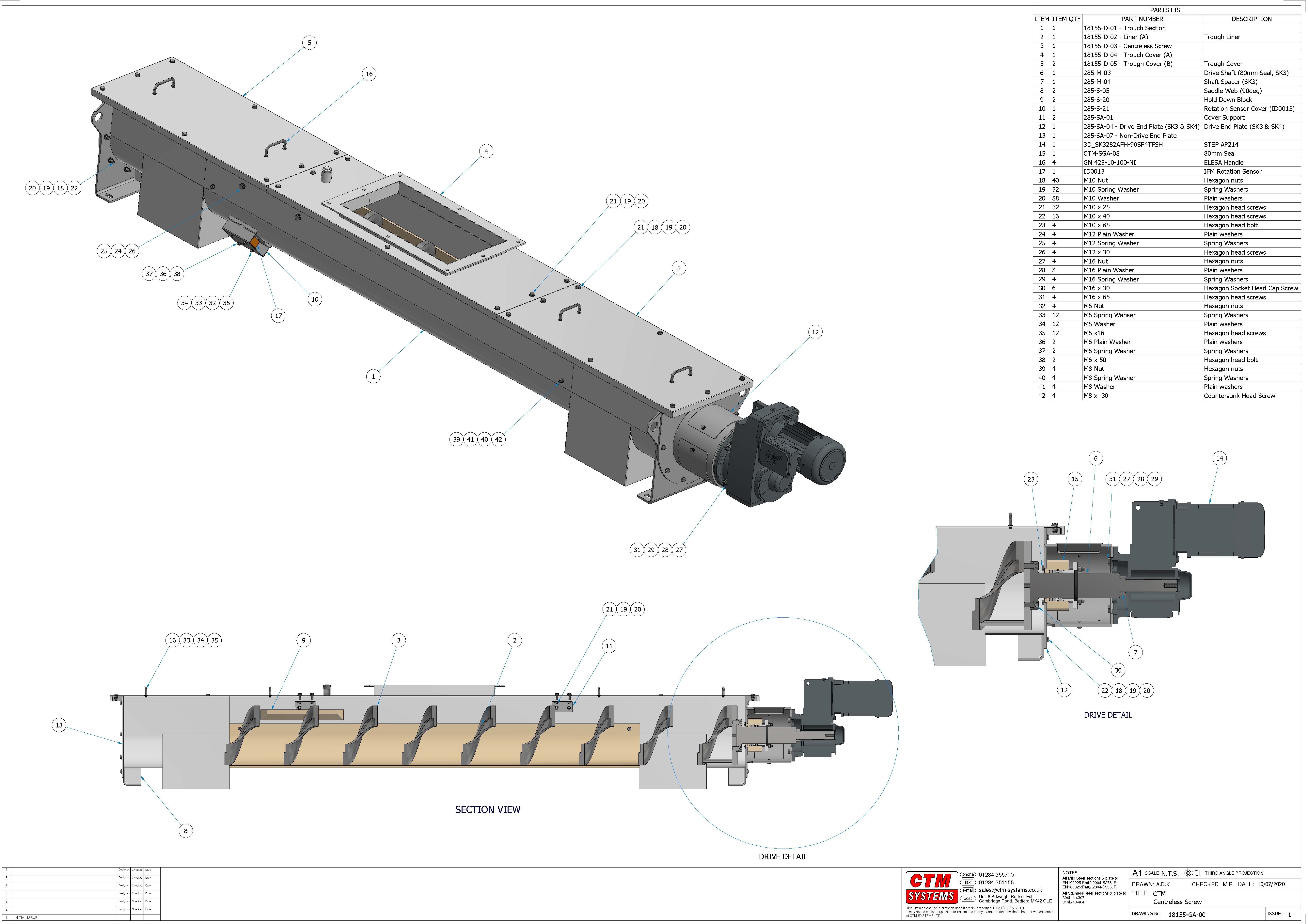

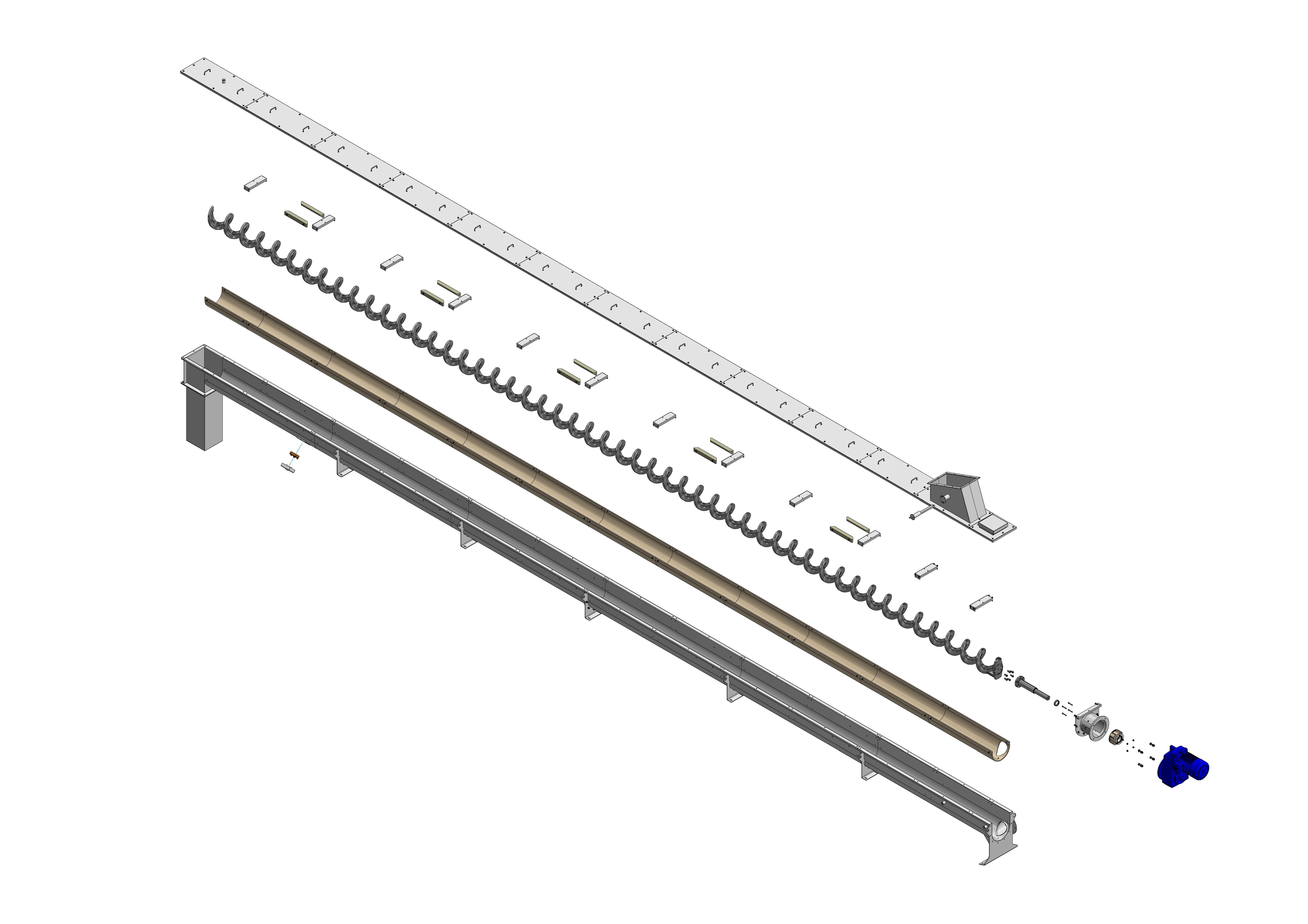

Centreless Screw Conveyors

CTM Systems centreless screw conveyors are recommended for applications which convey sludge type material such as sewage sludge, grit & screenings, waste materials, recycling processes, food waste and factory by-products. Casings generally of stainless-steel construction which ensures a long life span due the corrosion resistance of the materials used in manufacture. Mild steel painted casings are also an option. Internal painted finishes available to protect against acidic or corrosive materials. With equipment being supplied to various sectors for 25 years and proven track record of effective aftersales support client’s operations, our in-house knowledge of this technology is second to none.

The centreless spiral runs on a replaceable PE1000 liner which prolongs the life of the casing and allows the spiral to run on low friction surface, whilst conveying the product in question.

The benefits of using this type of conveyor are:

- Low maintenance

- Reliability

- Longevity

- Spillages eliminated

- Fully enclosed which in turn provides excellent odour containment. In addition to the fact all moving parts are fully guarded eliminating any Health & Safety issues.

Available in a bespoke range of lengths and throughputs.

This type of conveyor is particularly suitable for conveying moist, binding, and fibrous materials which would bind to a shafted type screw conveyor Centre tube; therefore, blockages and jam risk is designed out to ensure uninterrupted and efficient operation.

CTM Systems in house design facility can evaluate your requirement, supply a concept design, and provide costings to enable clients to make an educated decision on their materials handling solution. With payback quickly achieved due to low maintenance requirements and high reliability meaning prolonged operation with very little down time being the norm.

Please contact CTM Systems either by email: [email protected] or telephone Our Sales office who can advise the most suitable product in our broad range of conveyors to convey the product in your process. Tel: 01530 239181

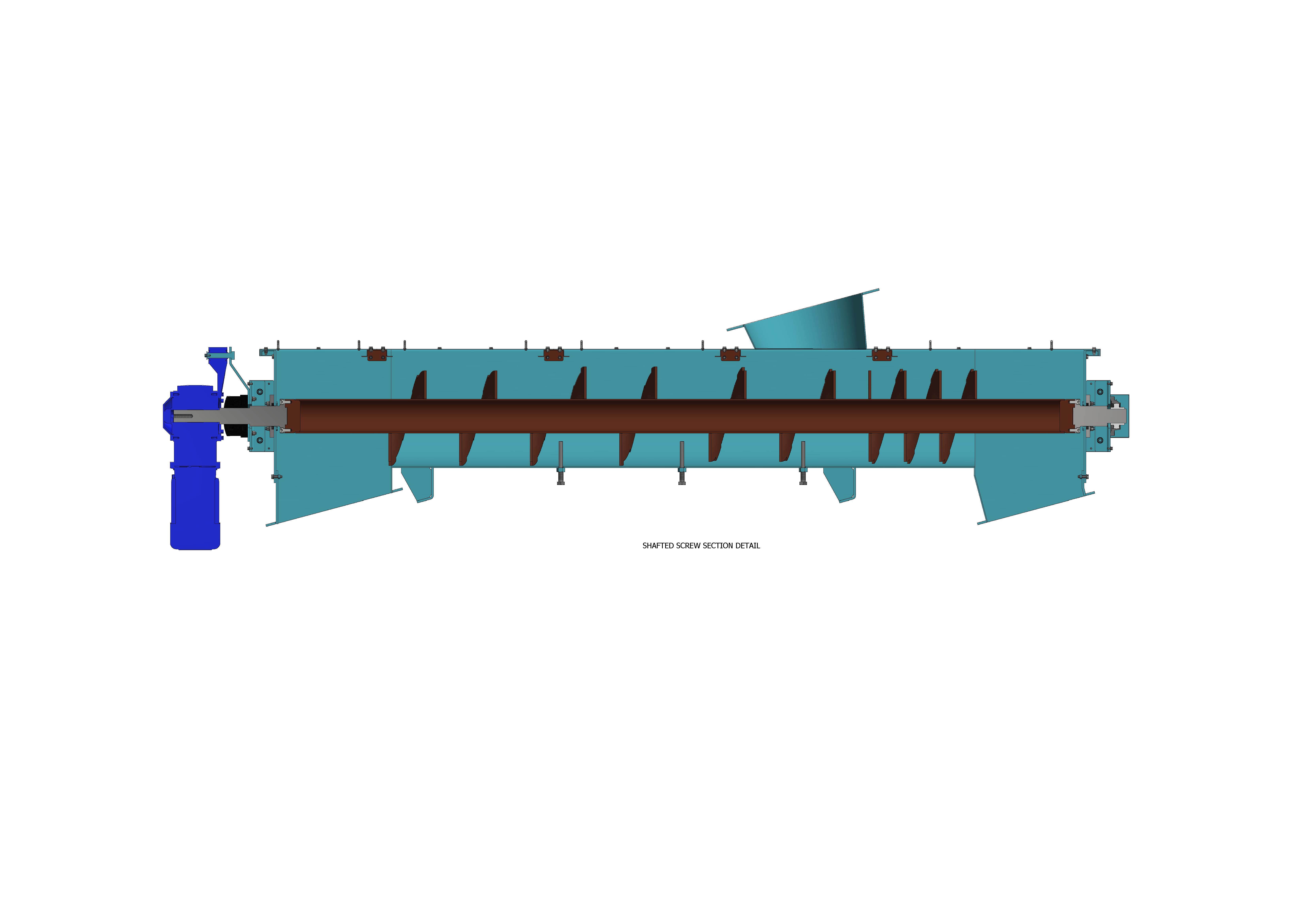

Shafted Screw Conveyors

These conveyors are used for all demanding applications and can be up to 10m in length with an unsupported centre tube and to 1m in diameter, longer spans can be achieved using hanger bearings or peripheral bearings. Flights can be any steel type including Abro M or Hardox, hard facing can be added for particularly abrasive applications. Or stainless steel for food applications or increased corrosion resistance.

Generally used for dry material transfer, with the fully enclosed casing providing a means of containing dust, also protecting the product being conveyed from the outside elements.

Stuffing boxes or shaft seals are fitted, ensuring no leakage occurs where the shafts pass through the end plates. Type dependant on liquid content.

Mild steel painted casings are also an option. Internal painted finishes available to protect against acidic or corrosive materials.

Drives can be foot mounted, shaft mounted or direct driven dependent on the most suitable for the application and environment. can be in mild steel or stainless.

Screw conveyors that has a solid shaft that goes through the flighting of the screw and has a bearing supporting each end of the centre tube.

Benefits: –

- Longer spans can be covered by the means of using hanger bearings or peripheral bearing blocks.

- A shafted screw generally does not need liners therefore they are lower maintenance.

- A shafted screw conveyor can operate at higher speeds due to the fact there is no liner.

- Fully enclosed which in turn provides excellent odour containment. In addition to the fact all moving parts are fully guarded eliminating any Health & Safety issues.

Please contact CTM Systems either by email: [email protected] or telephone Our Sales office who can advise the most suitable product in our broad range of conveyors to convey the product in your process. 01530 239181