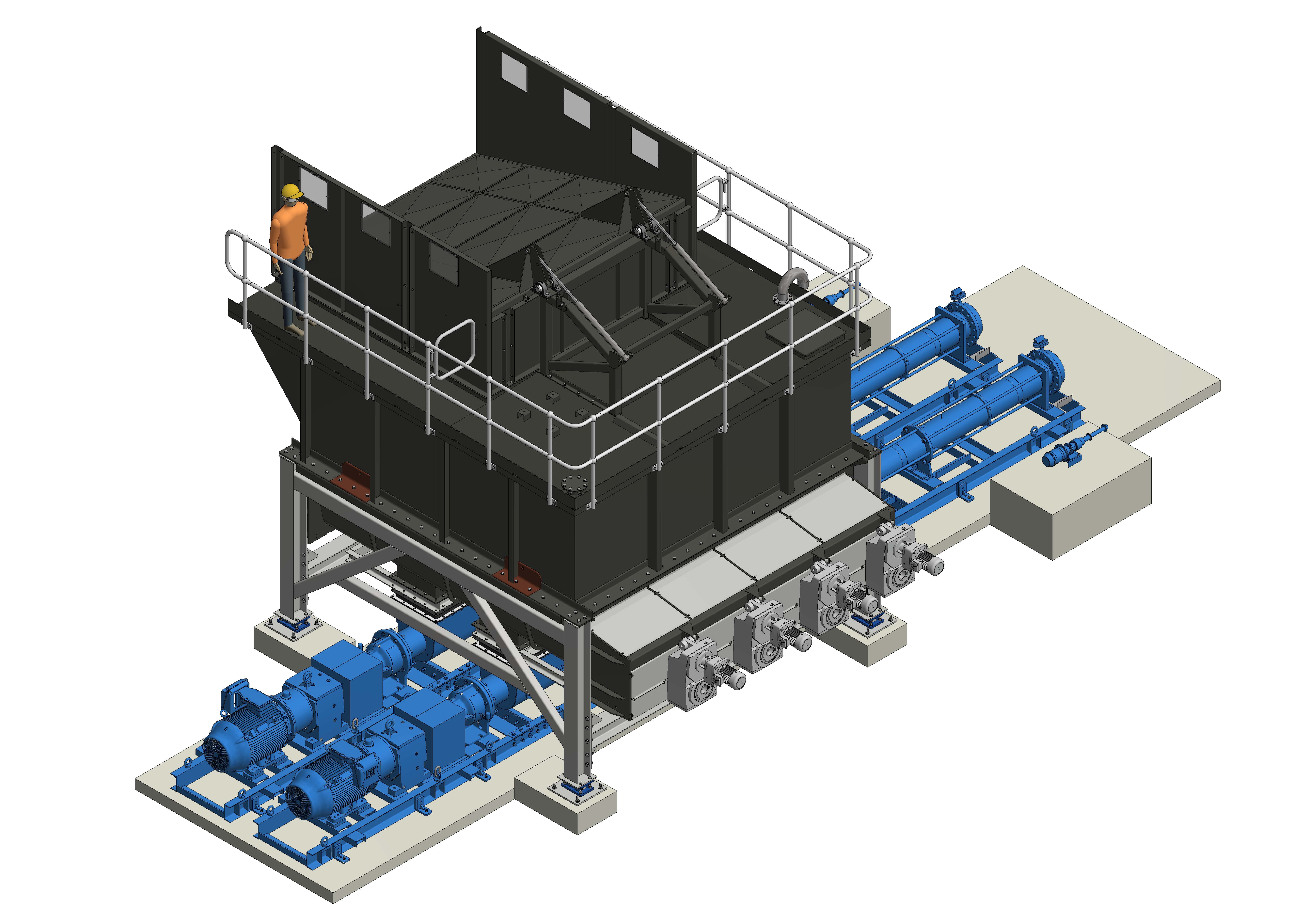

Live Bottom Bins

CTM systems live bottom bins and silo systems are designed specifically to suit to our client’s specification, with close communication throughout the design process to deliver an effective and maintainable engineering solution. With a proven track record in this field, our tried and tested design principles can be incorporated to produce scalable silo and live bottom bin capacities.

With many successful existing projects in the wastewater industry operating on a 24/7 basis storing, transferring, and discharging dewatered sewage sludge.

Single or multiple point discharges dependent on pan size and capacity.

Benefits

- Multiple screws typically 3-9 form a rectangular base of rotating screws which prevent bridging or any blockages of sludge. Ensuring the product is kept in a flowable state.

- Large diameter heavily constructed screw assemblies enable large torque to be transmitted to the product to cater for the characteristics of sticky material and allow a low discharge rates for pumps to deliver a constant flow. For the products onward transport.

- Low RPM reduces wear rates

- Shaft seals with wear elements allow for reliable operation and minimal maintenance.

- Direct drive through spur gears offer long life

Pumps

With collaborations with leading pump manufacturers we can offer a complete package including pumps, which eliminates any interfacing issues for the client.

Construction Materials

Mild steel or stainless-steel construction available selection dependent on product being conveyed and the specific environment.

WIMES paint specifications available, CTM Systems can advise the best material for construction and corrosion protection to ensure longevity of supplied products.

Push Floors

Are a very successful method of discharging non-free flowing materials from a flat bottom silo, which can be circular or rectangular in shape. The discharge areas are kept free flowing by the means of the reciprocating sliding frame.

Benefits

- Controlled discharge rate to coincide with pump operation

- Prevents bridging or blocking

- Reliable and low maintenance

- Vertical walls can be used in silo design optimising volume capability

- Quiet operation

- Can be used for lorry fed reception bunkers.

Please contact sales to discuss the capacity and throughput specification of your site design requirements.

Examples and testimonials on request [email protected] or contact Marc Brewster 01531 239181